Powering Digital Twins for Every Project Phase

From Design to Operations: A Connected Digital Journey

Acting as a single source of truth, O3 harnesses a robust Common Data Environment (CDE) to centralize data, ensure version control, and drive collaboration. Transform design information through intelligent BIM management and 4D/5D VDC planning, connect strategy to execution with Advanced Work Packaging, and embed change management across every workflow.

From real-time field execution and safety monitoring to systems completions and operations, O3 unifies the entire project lifecycle in one continuous, data-driven loop between the office and the field — delivering safer, smarter, and more predictable outcomes.

Common Data Environment

Common Data Environment

O3 provides a secure, centralized hub for project data, models, and documents. A true CDE ensures version control, enhances collaboration, and streamlines workflows across every project participant.

.png?width=23&height=22&name=Icon%20(7).png) Virtual Design & Construction

Virtual Design & Construction

O3 connects models, schedules, and costs to power 4D/5D VDC planning. Teams gain new clarity into execution priorities, improving collaboration and decision-making across the full project lifecycle.

BIM Project Management

BIM Project Management

O3 enhances BIM by transforming static models into dynamic digital twins. Real-time collaboration and data integration maximize BIM’s value from design through execution, creating a single, connected view of the project.

3D Model Data Parsing

3D Model Data Parsing

O3 automatically parses and organizes complex BIM data into actionable insights. With built-in rules and visualizations, teams can streamline work packaging, support change management, and enable precision-driven digital twin strategies.

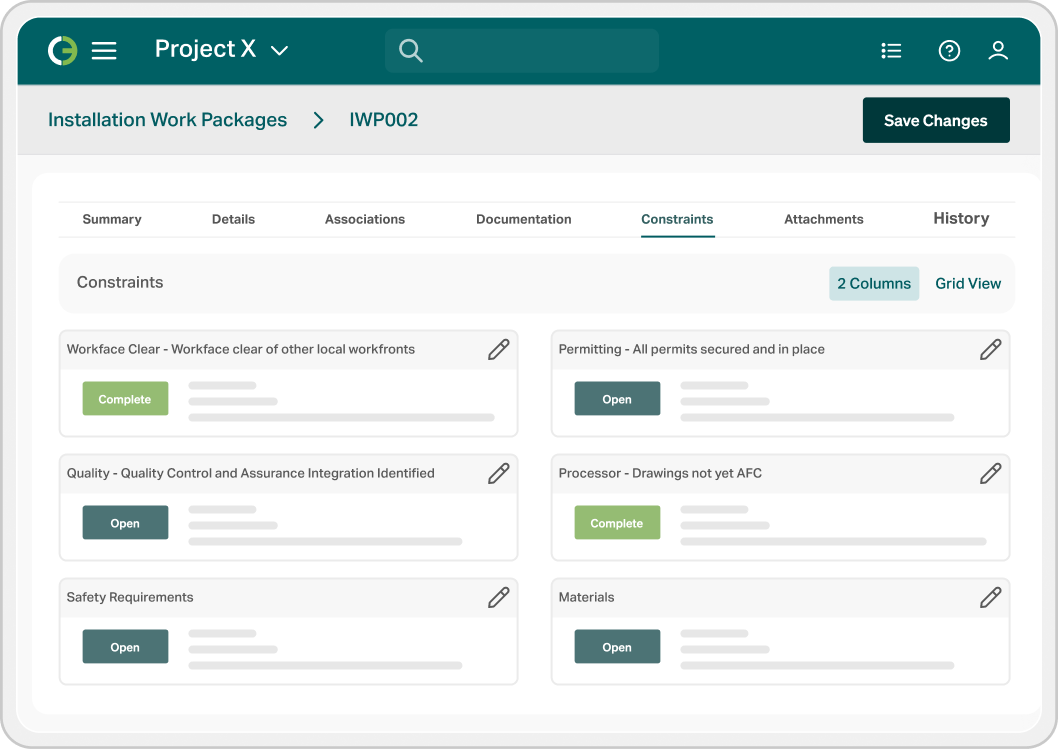

Advanced Work Packaging

Advanced Work Packaging

O3 links work packages directly to real-time model data, field status, and schedules. This integration allows stakeholders to visualize EWPs, CWPs, and IWPs in a 3D/4D environment for better planning, reduced idle time, and execution alignment.

Work Management

Work Management

Digital twins connect crews, tasks, and materials to daily work execution. Field users can update progress, receive assignments, and flag issues directly in the twin, streamlining workflows and eliminating reliance on static spreadsheets or paper.

Risk & Safety Management

Risk & Safety Management

O3 leverages digital twins for proactive risk detection and prevention. From identifying hazards to planning safe access routes, the digital twin embeds safety into every step, while integrating with incident tracking and compliance protocols.

Systems Completions

Systems Completions

Digital twins integrate completion status, test results, and commissioning data into a single view. Track readiness of mechanical, electrical, and instrumentation systems with precision, enabling faster commissioning, fewer surprises, and smoother handover.

Operations & Maintenance

Operations & Maintenance

O3 extends the power of digital twins into O&M. By integrating lifecycle data and predictive insights, teams can reduce downtime, extend asset life, and drive operational excellence.

Why O3 + Digital Twins Win

O3 takes digital twin technology from concept to execution, ensuring project teams unlock measurable benefits across scale and complexity.

- Centralized, connected data across the lifecycle

- Real-time visualization of work status and progress

- Faster commissioning and smoother startup

- Improved collaboration and accountability across stakeholders

- Predictable, on-time, on-budget outcomes

Delivering Measurable Value with Digital Twins

With O3, digital twins directly drive the metrics that matter most to Owners, EPCs, and contractors.

Boost Productivity with Live, Real-Time Visibility

Eliminate inefficiencies by keeping teams aligned and focused.

- Reduce idle time with live progress tracking

- Improve time on tools for field crews

- Simplify planning and coordination

Mitigate Risk Through Proactive Insights

Predict, detect, and prevent issues before they escalate.

- Identify constraints and hazards early

- Reduce disputes, claims, and compliance risks

- Maintain a single source of truth

Reduce Costs with Connected Execution

Optimize resources and minimize waste across the project.

- Cut rework and avoid change orders

- Reduce admin overhead and redundant tools

- Maximize workforce and equipment utilization

Increase Revenue with Stronger Delivery Performance

Win more bids and accelerate project returns.

- Strengthen proposals with proven results

- Improve cash flow with faster closeout

- Build lasting client trust and repeat business

We explored various solutions, but the decision was made to leverage the highly customizable system configurations and user flexibility that O3 brings to the table.

The Future of Project

Execution Starts with Your Digital Twin

Digital twins only create value when connected to real execution. O3 makes them practical, powerful, and scalable for every project.