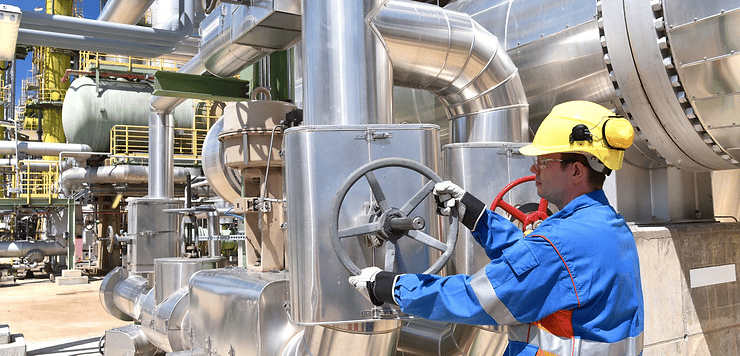

It’s common theme in industrial construction to employ work packaging when dividing projects into manageable sections of work for engineering, procurement, and construction. But employing true Advanced Work Packaging (packaging work across all project phases – not just Construction Execution) is not as common. Yet.

Advanced Work Packaging (AWP) is the organized and structured approach to provide the all information needed to execute work from start to finish on a project, even as early as the Concept phase. AWP provides enormous benefit to the project including increased productivity and project predictability in terms of cost, schedule, quality, and safety.

The Construction Industry Institute (CII) has developed a life cycle execution model that encompasses recommendations for implementing Advanced Work Packaging throughout a project. The model is built on industry best practices based on team experiences and expertise.

LOW PRODUCTIVITY

The US construction industry has been slow to adopt improvements in labor productivity for the past 40 years. Improvements in labor productivity present an obvious impact to overall project costs and schedules since labor represents roughly 40-60% of project costs.

The reasons for low labor productivity come from poor coordination between engineering and construction causing rework in addition to poor planning of material procurement.

When projects are properly planned, constraints are drastically reduced and avoided.

DIFFERENCE IN WORKFACE PLANNING AND WORK PACKAGING

Work packaging is the overall process flow of all the detailed packages. It is the planned, executable process for EPCs from design to execution. Whereas, workface planning is the process of organizing and delivering all the elements necessary, before the work is started, to enable each discipline of work to be safe, effective and efficient. The largest difference is that work packaging can begin in the early phases of a project while workface planning – as indicated by it’s name – is meant primarily for use at the workface during construction execution.

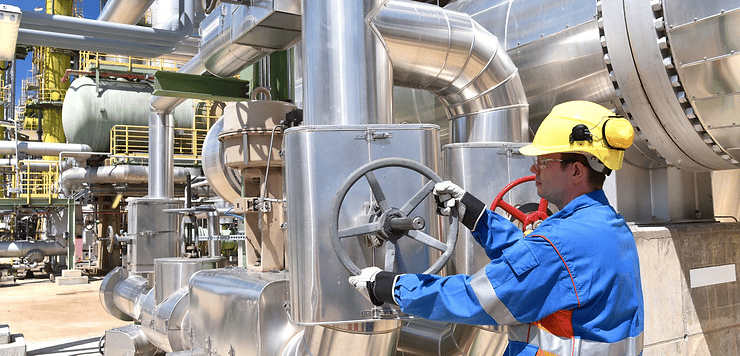

THE NEW ROLE FOR THE WORKFACE PLANNER

The workface planner is crucial to the success of leading the work packaging process. The workface planner is responsible for developing the Installation Work Packages (IWPs) and handling material procurement. It should come as no surprise that technology enhances the ability to track and monitor constraints for the planner. O3 Solutions offers a software platform built for workface planners to create digital work packages, track and monitor constraints in real-time, and view the status and progress of each work package.

BENEFITS OF AWP

The use of work packaging encourages planning, accuracy, and mitigates constraints and roadblocks. Responsibilities do not change for personnel when employing AWP but instead made work easier with the assistance of planning, better structure, and more resources available.

THE COMPANY BUY-IN

Success for Advanced Work Packaging is dependent on all sectors buying in to the process from corporate, to project management, to site supervisors. It’s a domino effect that starts with corporate support and trickles down to systems in place to effectively utilize workface planning. If one leg of the system is not buying in, then the system will not succeed.

SIZE DOESN’T MATTER

The size of the project does not matter when employing Advanced Work Packaging processes. While most of the documented success stories are primarily on very large projects, the methodology has been proven to be effective on all project sizes. The successful implementation of AWP on projects saw significant cost and schedule savings, as well as quality and safety improvements – and that’s in direct correlation to the value of workface planning and work packaging.

TECHNOLOGY DOES MATTER

Successful implementation of Advanced Work Packaging is greatly enhanced by the use of technology. Software for work packaging, scheduling, project management and progress, and modeling can help speed up the adoption of the methodology because the benefits and time savings are easily recognizable in day to day life. The key to using technology is having integrated systems, meaning the systems are sharing information through automation versus manually entering data. Real-time data and reporting instantly cuts time on effort and reduces error prone manual processes.

O3 SOLUTIONS

O3 is a digital platform purpose-built for owners, EPCs, and contractors working on industrial capital assets. O3 helps maximize Advanced Work Packaging by setting the conditions for success during implementation, facilitating best practice adherence during execution, driving continuous improvement and scaling over time. O3 adds value to all stages of AWP maturity, no matter where you are in the AWP journey.