The final installment of our data series focuses on using data to support work packaging with a 3D model. 3D modeling has come a long way in just the last few years. It would take quite a bit of time to create the 3D model and when it was ready it was pretty but it wasn’t totally functional in the sense that you couldn’t select a piece of it to see specific properties. For example, if you were to select a pipe to see its properties, it would show a triangle. It was disappointing, to say the least. Fortunately, those days are behind us and we’re in a much better position now with data exchange.

The Value/Benefits of Data to Support Work Packaging with a 3D Model

We can use 3D model data directly from the models for the construction scope. There’s no need to export the 3D model data to other formats such as excel or CSV and then use the data in speared sheets for planning or construction use. The user can visualize the objects that are going to be built and do a visual inspection with their relevant data. 3D models can be linked with many other resources such as drawings, bill of materials, documents, schedules, and more. All of the related information needed for construction can be accessed through the 3D objects in an organized way. When we generate work packaging by using 3D models, along with the packaging information, we can also include screenshots of 3D objects as visual documentation. Visual reporting, like 3D model colorization based on data, such as status, constraints, approvals, progress, etc. will be highly beneficial. These only highlight some of the benefits; there are many more.

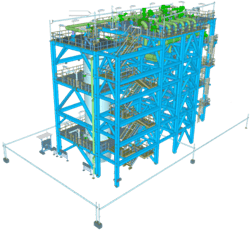

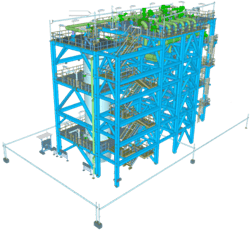

3D Model

3D Models are created during design time and widely used for design verification, multidiscipline coordination, clash detection, visualization, etc. The investment made in creating a 3D model should not be limited to the scope, but rather extended to the construction phase as well.

3D Models have many disciplines including piping, equipment, structural steel, electrical, instrumentation, concrete, and HVAC. Each discipline’s objects are different as well as the purpose and methods of construction. Disciplines also need a certain set of mandatory properties to use for the construction scope. Some information like fabrication data will not be directly available in the design 3D model, so a provision to update 3D model data is needed with the fabrication information. Some disciplines like piping, steel, and equipment can be used without many enhancements to get the needed data for the work packaging scope if you’re using the correct tool. O3’s ONBuild solution provides a state-of-the-art solution to use 3D model data efficiently in work packaging.

3D Model Data Framework

ONBuild Construction Component framework is a highly flexible and dynamic framework. This feature enables users to use 3D model data effectively in work packaging. The framework is designed in a way that the user can create construction components based on data collected and conditioned from various sources such as 3D model data, fabrication data, calculated or derived based on other data. We can also import external data and include them to create a Construction Component enriched with all these data from different sources but for the same purpose.

The construction component is discipline-specific, it can contain one or many 3D model objects. The same 3D model object could be used in a different work packaging scope, so we allow the same 3D object to create construction components for different work packaging scopes. For Example, 3D objects used for fabrication work packaging can later be used for erection work packaging in a different combination. ONBuild Construction Components can be created even without 3D model data.

3D Model Data: Piping, Steel & Concrete

In piping, we can usually see two types of data. Design data and fabrication data. When we use a 3D model for work packaging, design data and fabrication data could be incorporated into the work packaging.

Design data will detail the pipeline up to the isometric level. When the purpose of work packaging is fabrication then the construction component can be created at an isometric level with the needed fabrication information.

O3 ONBuild has a very advanced PCF processing algorithm; we calculate additional information that is needed for construction or “good to have” for construction and add them to its spool level or piping component level.

The steel model is also similar to the piping discipline. In steel design models we get data for steel members and plates etc. For the construction work packaging scope, especially for the erection scope, we need 3D model data from the fabrication models. Design 3D models will be detailed in the detailing software like Tekla Structures. In the detailing process, the structural members that can be prefabricated in a fab shop will be identified and grouped based on engineering details. Then a unique identifier for the group will be assigned. For the erection scope, this assembly will be a single unit in the construction site for the erection.

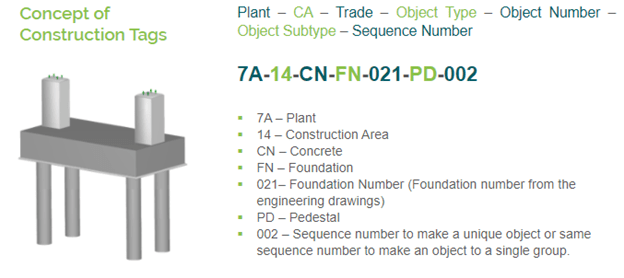

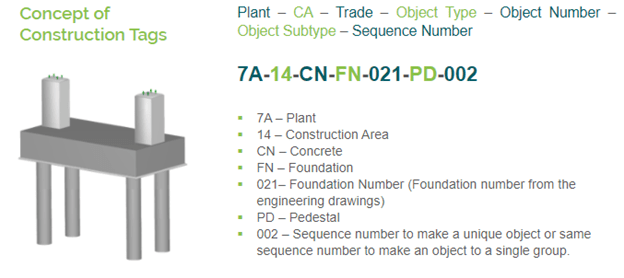

In order to use concrete efficiently in work packaging, 3D concrete objects should have certain properties. As a reminder, in some disciplines, objects can be used more easily than others. In most cases like piping, steel, and equipment, the objects from these disciplines are well organized and tagged. Equipment will have equipment names, piping will have isometric names, and so on. In many cases, a discipline like concrete may not have this information in a 3D model. This is one of the reasons why we struggle a bit to use concrete in work packaging.

The ONBuild concrete construction component needs mandatory information like an object tag. Objects should be modeled based on the construction sequence. In many cases, we have seen that the concrete will be modeled without seeing its construction sequence.

O3 uses Autodesk Forge for 3D visualization.

It’s important for us to work with our clients from the very beginning and prior to starting any project. We set agreements for data on how it’s needed, not only for 3D models but also for the complete AWP implementation scope. It’s critical to successful implementation.

For more information schedule your personalized demo today!