Scalable Advanced Work Packaging (AWP) is real and not too expensive to bring meaningful returns on small cap, brownfield projects with a TIC as low as $50k. From $50k to $50B, AWP is the right answer for efficient & safe project execution.

If you’re an owner and you aren’t doing scalable AWP on your small cap brownfield projects, you are already behind. If you think any of these excuses are valid, you’re incorrect:

- AWP is only for large cap projects

- Change Management is too hard at existing facilities

- AWP software is cost prohibitive for small projects

- There is no ROI for AWP on small cap projects

While it is true that deploying AWP on small cap projects has some unique challenges that you don’t find on most large cap greenfield projects, the overwhelming evidence is in: small cap AWP works and it works at scale! O3 paved the way for this by being the first company to do scalable AWP with entire programs of small cap projects being managed at existing owner facilities.

One challenge that we often see at small cap projects is that most of these brownfield projects don’t have sufficiently attributed engineering models to drive automation. That’s okay. Non-graphical WorkFace Planning and disciplined constraint management still add significant value. Owners have documented as much as a 20% increase in field productivity without the use of any graphical WorkFace Planning. The automation that results from a well attributed 3D model certainly brings efficiency to the AWP program, which leads to a reduction in the cost and number of WorkFace Planners that are required. At the end of the day, however, the majority of the field productivity benefits come from better planning and improved constraint management not from slick 3D model interfaces.

Another objection we often hear is that change management is too difficult at existing facilities. It is true that the change management challenge tends to be greater at existing operating facilities, but it is certainly not insurmountable. We have found that introducing change at existing plants can be a greater challenge due to the more engrained nature of the systems and processes. Often the same personnel have been doing the same job the same way for decades. This leads to more institutional inertia that has to be overcome. In greenfield environments, you have a new team coming together for a new scope so the ability to introduce change can be greater.

The advantage of small cap brownfield projects however, is that you have an evergreen portfolio of projects with rolling start dates that allow you to introduce change slowly over a series of multiple projects. In large cap greenfield projects you have to introduce all of the change at once and then lock in your project execution approach for the duration of the project. With small cap you can follow a “crawl, walk, run” approach over the course of several projects while limiting the change being introduced on any one project. This also has the added benefit of allowing you to learn lessons quickly and apply them to subsequent projects, which helps to refine your AWP process. What we have seen work well is the initial introduction of just Installation Work Packages, followed by the expansion to properly managed and released Construction Work Packages and then expansion both upstream and downstream into engineering and testing.

Another advantage of change management at operating facilities is the owner often serves as the construction manager which means that the owner has more ability to drive change in how the projects are executed than in some greenfield environments. Smaller embedded site contractors tend to be more amenable to these owner-driven changes than some of the larger EPC firms with more established systems and processes. Also, with embedded contractors, the delays associated with a bidding process can be removed, making it easier to get the contractor’s input during the engineering phases, when they can help to influence the design and lower the overall TIC with effective constructability and planning.

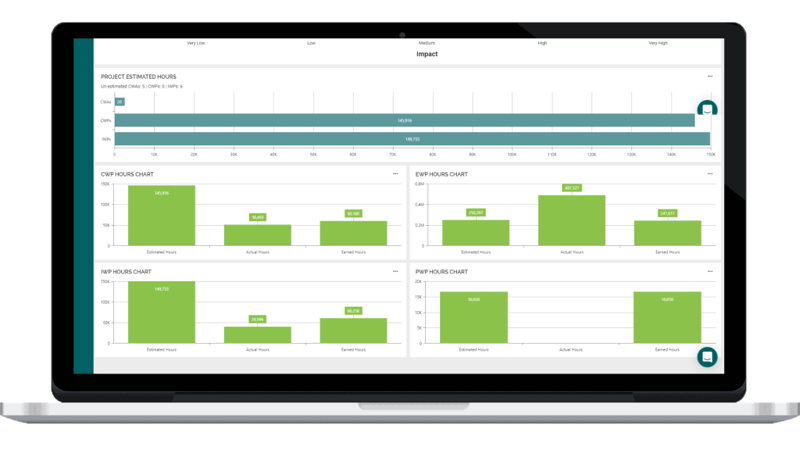

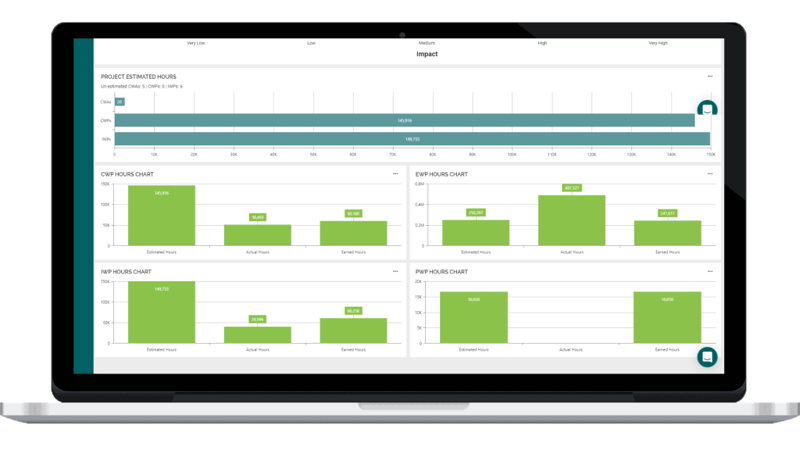

Another objection to scalable AWP that we have heard is that software tools are cost prohibitive for small cap projects. While this used to be the case, it is no longer true. With the emergence of web-based solutions that do not require expensive hardware to support thick client on-premise deployments, the total cost of ownership of AWP software solutions has decreased significantly. O3 has seen success with the rollout of its software across entire portfolios of small cap projects which further helps to defray the cost. Legacy on-premise solutions that do not support multiple projects and lack the ability to provide cross-project reporting are not a good fit for scalable AWP but these dinosaur technologies are on their way out. Modern, web-based tools like O3 are the future of construction software.

Example of cross project reporting across a portfolio of small cap projects in O3

Some Advice for Launching your Scalable AWP program

- Implement AWP on your small cap projects at existing facilities. If you aren’t doing AWP on your small cap projects, you are behind. AWP works for small cap offshore, onshore, chemical, Oil & Gas, Power, etc. The project type doesn’t matter, the value is there.

- Avoid the trap of trying to implement AWP on projects that are already in the field. Focus on the new projects coming through, or those that are still in the FEL stages.

- Target the right project to use as a pilot, with a project team that has a proven track record of being responsive to change and open to new strategies.

- Subsidize the AWP pilot from either the corporate or the portfolio AWP program so the project manager of your pilot project doesn’t have to bear the costs on his budget. This reduces the risk to them and makes them more on-board with bringing the new process and technology into play.

- Once your pilot is complete, go for the entire portfolio as quickly as possible. Don’t have multiple simultaneous project execution approaches running on the same facility; it can be confusing and lead to a reduced ROI.

- Avoid legacy software solutions that require thick client, on-premise deployments that are cost prohibitive for small cap projects.

- Spread the costs of AWP across a portfolio of projects by sharing resources such as WorkFace Planners, AWP Information Manager, AWP lead. With small cap projects you do not need to have a dedicated resource for each project.

To learn more about how O3 can enhance your projects, schedule your personalized demo today.