It is no secret that the construction industry has been one of the slowest to make the digital transformation. That is crazy to think about considering construction is one of the largest sectors in the world economy.

Productivity is a massive problem across the industry. Productivity gains have essentially been stagnant. Safety has also been flat in terms of performance. For productivity and safety to improve a massive shift must begin through the adoption of new approaches to work and project management.

This shift has begun to take place at the Owner Operating Facility level for industrial construction projects. There has been a significant change in the safety performance since seeing Owners take on a more prominent role in adopting a new productivity methodology.

This methodology is Advanced Work Packaging. Construction Industry Institute recognizes Advanced Work Packaging as a best practice. It is defined as the overall process flow of the detailed work packages, essentially “beginning with the end in mind”. This process is finally moving construction from being known as stagnant in terms of productivity to one of innovation. The benefits to implementing AWP include savings up to 10% of the projects Total Install Cost and productivity increase up to 25%.

However, this process is still new and taking some time to become widely adopted. But with Owners and Operating Facilities leading the charge, it is forcing EPCs and Contractors to find ways to truly implement it into their contracts and bids.

However, this process is still new and taking some time to become widely adopted. But with Owners and Operating Facilities leading the charge, it is forcing EPCs and Contractors to find ways to truly implement it into their contracts and bids.

There are several ways O3 has seen Owners engage with adopting AWP from Lump Sum EPC/M engagements, Active Construction Management Role in Mega Projects, Small Cap Operating Site Programs to Corporate AWP Program Management.

We have found that to successfully implement AWP Owners need to include contractual language with specific data exhibits. Early adoption is critical as well, meaning the ability to influence decreases drastically post contract. Support from the top down is also integral to change management. When an EPC is taking on a new methodology or process required by the Owner, they must have the tools to do so or the process will fall apart.

Owners are the only one over the entire project, so visibility into it is paramount. Owners are also the only ones in a position to drive collaboration across the silos of contractors.

Owners can drive this by clearly defining AWP expectations and include contracts to remove uncertainty. Owners can also take a partner approach to provide resources to contractors to “level-up” their AWP maturity.

The bottom line is Owners are rewarding contractors that have invested in AWP during bidding to encourage adoption. While this may seem daunting to an EPC or Contractor there are many benefits to having the Owner involved in the AWP adoption.

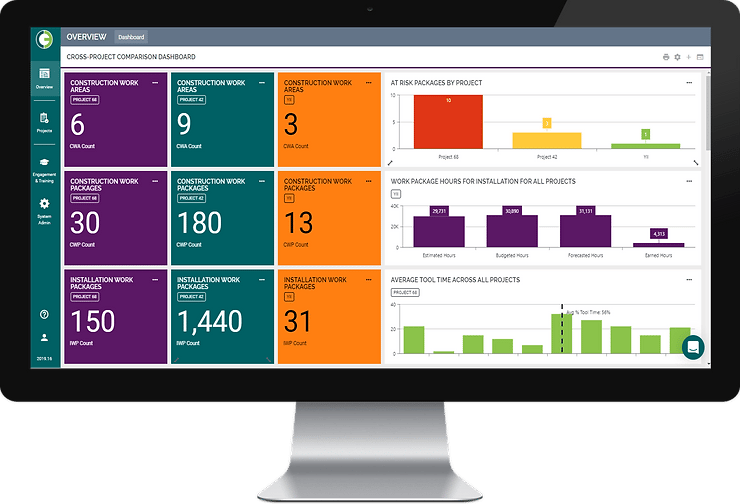

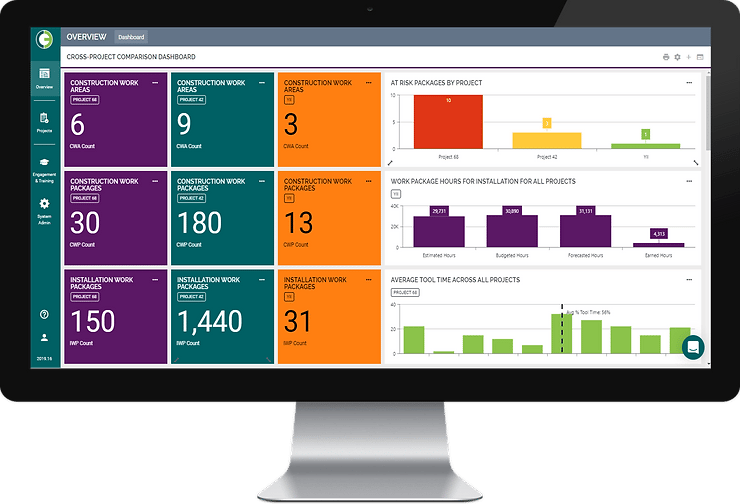

O3 provides the tools for Contractors to support an Owner’s AWP program. Our suite of solutions are designed to improve productivity on projects of all sizes. Specifically, our ONPlan solution features the digital tools to standardize your AWP program across your organization. ONPlan is purpose-built to consume data from existing tools throughout the entire lifecycle of a project to identify potential areas of improvement, help track and manage work across multiple teams and work package types and manage constraints that might be holding up work.

However, this process is still new and taking some time to become widely adopted. But with Owners and Operating Facilities leading the charge, it is forcing EPCs and Contractors to find ways to truly implement it into their contracts and bids.

However, this process is still new and taking some time to become widely adopted. But with Owners and Operating Facilities leading the charge, it is forcing EPCs and Contractors to find ways to truly implement it into their contracts and bids.