WHAT IS AWP?

CII has defined Advanced Work Packaging as a best practice that will enhance a construction project’s performance when executed properly. AWP methodology is “the overall process flow of all the detailed work packages (construction, engineering and installation work packages). AWP is a planned, executable process that encompasses the work on an EPC project, beginning with initial planning and continuing through detailed design and construction execution. AWP provides the framework for productive and progressive construction and presumes the existence of a construction execution plan.”

WHO IS RESPONSIBLE FOR AWP?

Owners and Operating Facilities are driving the adoption of Advanced Work Packaging. More and more owners are adopting and mandating the best practice and have inserted it into their procedures and contract documents.

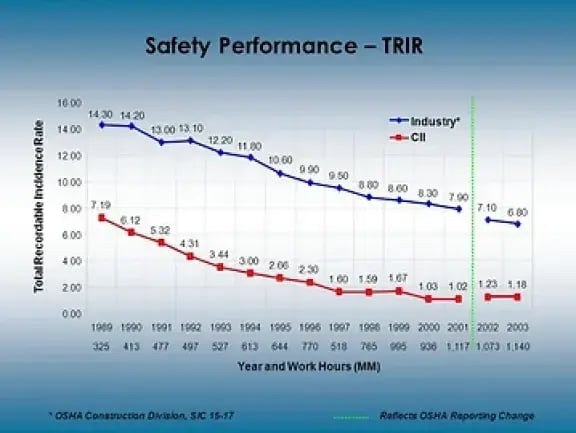

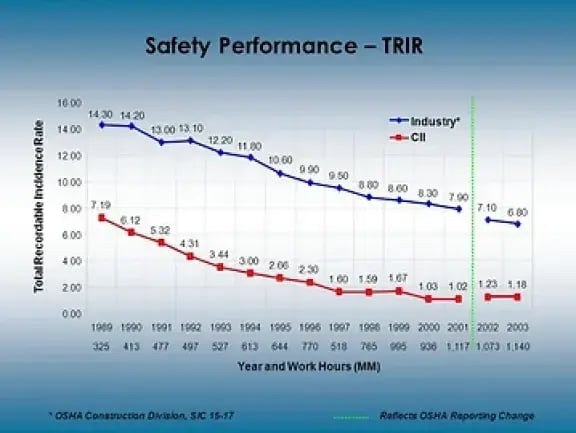

It’s important that owners drive it because without them AWP will not transform the industry. A great example of owners adopting AWP is the safety as a model for productivity graphic. This shows that performance was flat but then improved with the implementation of an AWP program.

Owners are driving the adoption of an AWP program by setting specific requirements, standards, incentives and gaining the ability to measure performance. This is also a proponent in shifting from lagging to leading indicators.

The types of owner engagement projects include Lump Sum EPC/M engagements, Active Construction Manager role in Megaprojects, Small Cap Operating Site programs and Corporate AWP Program Management.

LUMP SUM EPC/M ENGAGEMENTS

O3 Solutions engages with this type of owner with an approach that “hope is not a strategy.” O3 has found that owners that are AWP mature take a trust by verify approach, and they are doing so by gathering data. O3 supports this by providing data and allowing Owners to draw their own conclusions. This is done by setting contract data requirements. Owners that are truly driving AWP success acknowledge that the responsibility can’t be placed at the contractor level and that their owner control is limited while risks are not limited.

TOOLS USED FOR LUMP SUM EPC/M ENGAGEMENTS

Tools are focused on AWP reporting and Analytics. O3 Solutions offers ONPlan with is a robust plan featuring reporting and analytics in addition to AWP Best Practice measurement and data management. O3 also offers ONTrack which is agile project management in early phases.

RESULTS FOR LUMP SUM EPC/M ENGAGEMENTS

O3 has seen 3% of total install cost saved through contingency elimination. The results include

- better scoping of projects

- reduction in contingency

- reduction in change orders

- improved owner visibility

- schedule and cost certainty

ACTIVE CONSTRUCTION MANAGER ROLE IN MEGA PROJECTS

O3 Solutions engages with type of owner with an approach of “begin with the end in mind.” This means starting from the very beginning with understanding the change management process. These projects are successful due to early engagement. The owner is the only one involved in the early phases and setting up AWP in the beginning is critical. O3 has been used for transformation team management for successful implementation. This enables full AWP adoption through execution.

TOOLS FOR ACTIVE CONSTRUCTION MANAGER ROLE IN MEGA PROJECTS

Tools are focused on full project Advanced Work Packaging. O3’s ONPlan features AWP and data driven reporting. ONPace is purpose-built for WorkFace Planning. ONTrack is used for agile project management. ONTask is used for global task management and ONCourse is great for training management.

RESULTS FOR ACTIVE CONSTRUCTION MANAGER ROLE IN MEGA PROJECTS

Some of the results that we’ve seen where there has been an active construction management role include:

- 12 Digital Meetings powered by data-driven dashboards

- Replaced pdf contractor reports with real-time data-driven dashboards

- Contractor early planning facilitated better implementation of constructability and feedback into engineering

- Enhanced team goal tracking and planning

- More accurate engineering status tracked by package closeout

- Better engineering constraint management

SMALL CAP OPERATING FACILITIES

The approach used on this project is a “crawl, walk, run.” It’s the portfolio approach that takes advantage of small cap projects that occur frequently. This allows for measuring tool time on a recurring bases across AWP and Non-AWP projects. It also allows you to establish a path to self-sufficiency. In order to scale AWP across your portfolio you have to become self-sufficient.

TOOLS FOR SMALL CAP OPERATING FACILITIES

The tools we recommend for operating facilities include a suite of portfolio management solutions including ONPace for WorkFace Planning and Scaffold Management, ONPlan for Engineering Packages and Startup Packages and ONTools for Time on Tools Tracking.

RESULTS FOR SMALL CAP OPERATING FACILITIES

The results realized on some operating facilities while using O3 to implement AWP include an 18% increase in direct field labor on AWP vs Non-AWP projects.

- Zero to self-sufficient AWP program in 12 months

- 18% increase in direct field labor

- 25% increase in overall productivity

- Improved planning for access and critical lift tracking, reduced labor cost and risk

CORPORATE AWP PROGRAM MANAGEMENT

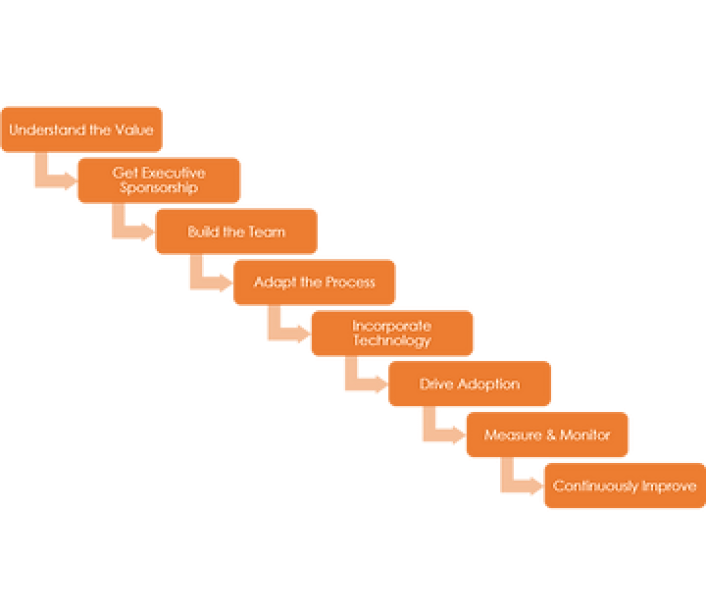

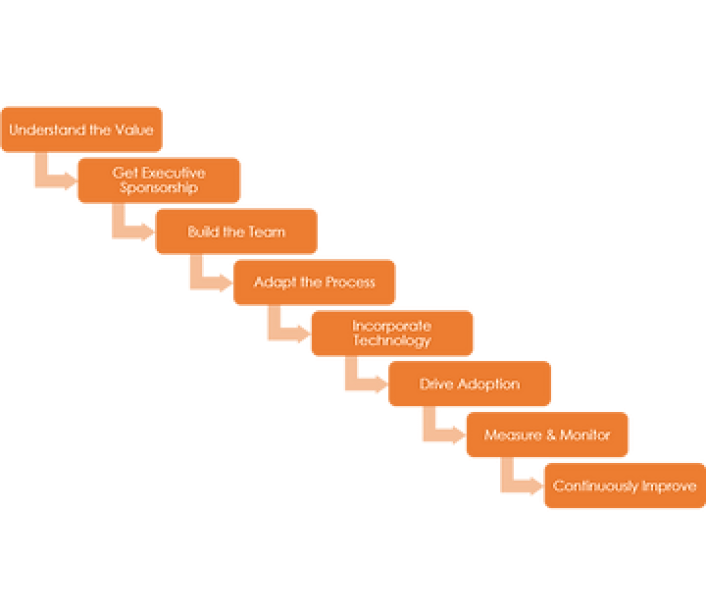

O3’s approach to this project is “righ-sizing AWP.” Defining your AWP program can be different for each project and establishing the correct project path is critical before beginning. O3’s services to assist in this include:

- Project archetype definition

- AWP goals and objectives

- AWP KPIs and metrics selection

- AWP implementation plan and roadmap

- System and processes map

- Roles and responsibilities

- RASCI & Org charts

- Training plan

- Program branding and awareness

TOOLS FOR CORPORATE AWP PROGRAM MANAGEMENT

Some of the tools O3 offers to accomplish your AWP program management goals include ONTrack for deliverable management, approvals management and risk management, ONTask for action tracking and ONCourse for Training Management.

RESULTS FOR CORPORATE AWP PROGRAM MANAGEMENT

The results we’ve seen from an AWP Program Management include implementation on all projects with over $500k in total install cost plus:

- Defined AWP across project archetypes

- Rolled AWP out to 15+ projects in 18 months

- Launched corporate AWP Library

- Published AWP education video

- Established standard work package templates

- Defined standard policies and procedures

- Developed standard contract language

BENEFITS OF OWNER INVOLVEMENT

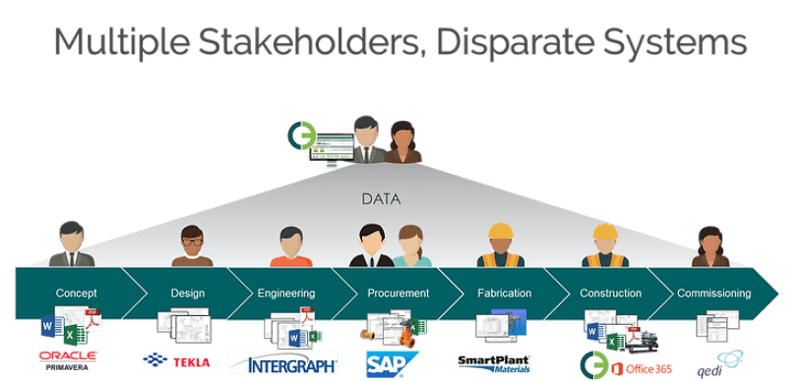

Owners see many benefits to implementing an Advanced Work Packaging program on projects. Constraint management allows owners to see that there may be more than realized. Owners care about total project optimization not just a portion. Owners are in a position to drive collaboration across silos and owners need to drive AWP to eliminate silos due to project visibility.

OWNER CONTRIBUTIONS

Owners need to clearly define AWP expectations and include in contracts to remove any uncertainty. Owners need to reward contractors that have invested in AWP during bidding to encourage adoption. Owners also need to take a partner approach and proved resources to contractors to “level-up” their AWP maturity.

Owners are driving the adoption of an AWP program and O3 offers the solutions to ensure it’s success no matter what size, type or maturity of a project.