The Importance of Data Integration

In the construction industry, waiting for a perfect 3D model with all the necessary data for work packaging is often an unrealistic expectation. Recognizing this challenge, O3 Solutions has developed powerful data integration capabilities that provide access to necessary data for effective work packaging, even with incomplete or imperfect data.

Handling Imperfect Data with O3’s Powerful Integration Capabilities: Effective Strategies for Data-Driven Insights

How O3 Overcomes Challenges of Imperfect Data

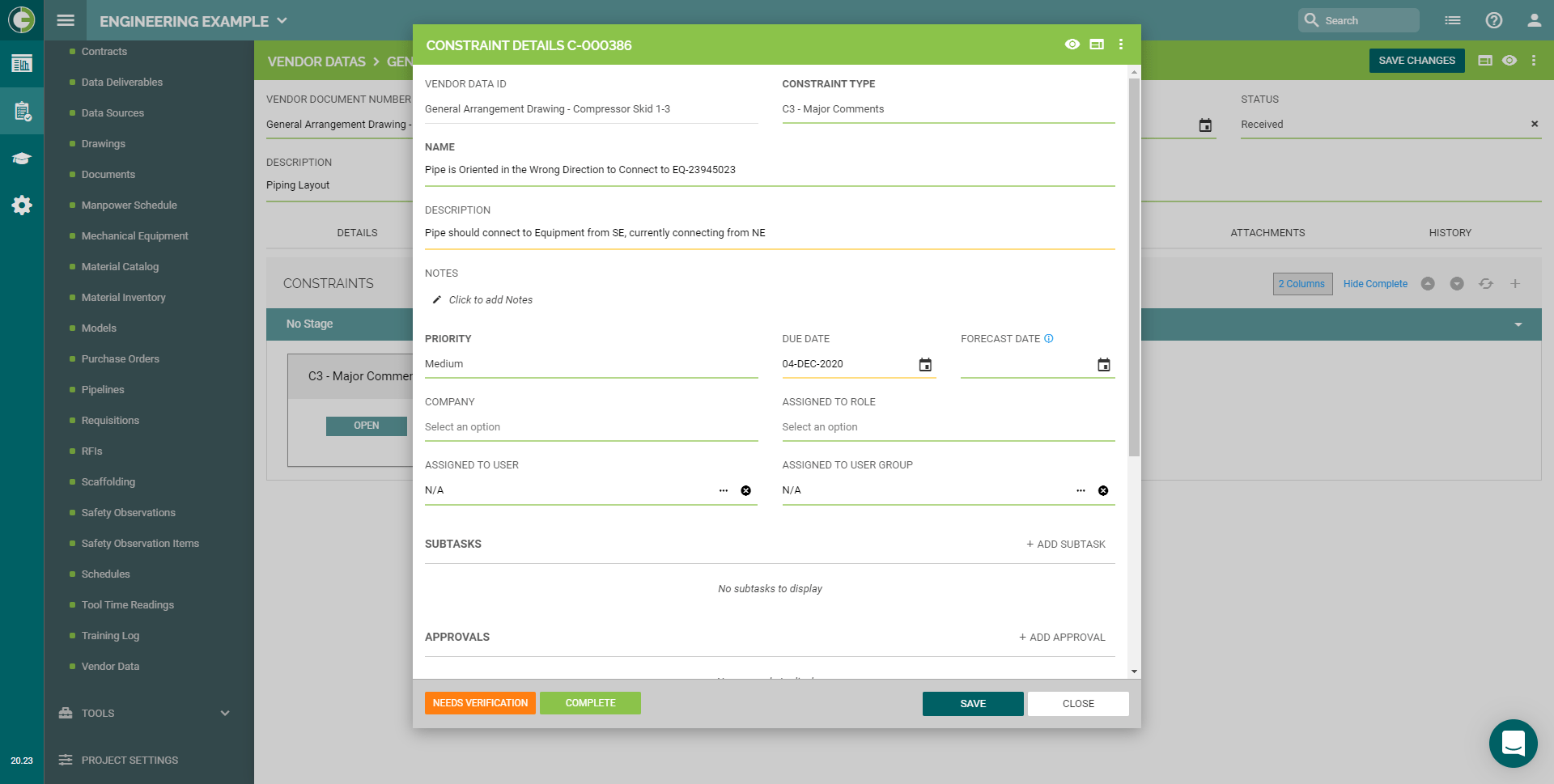

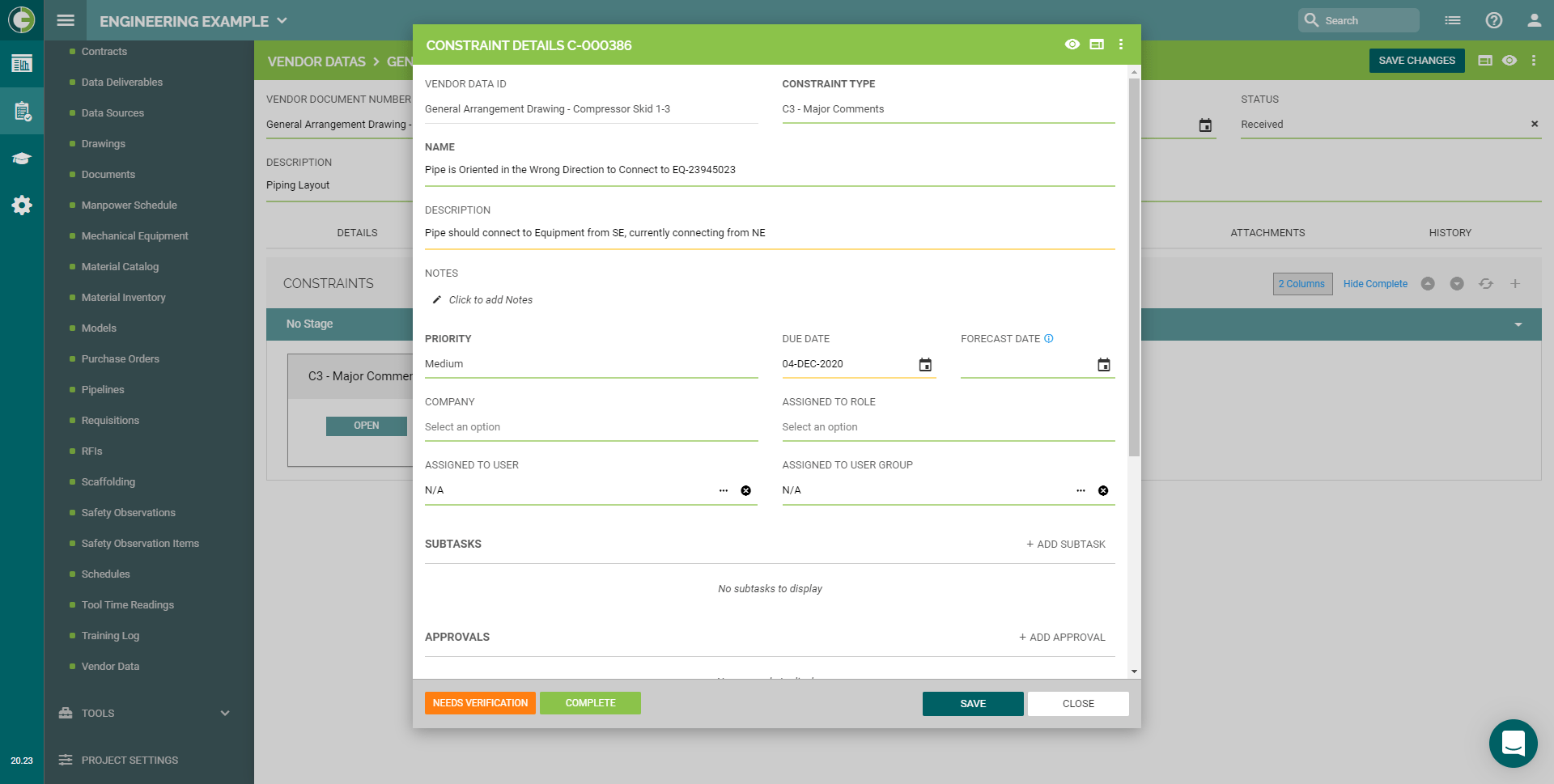

O3 Solutions can seamlessly integrate missing data into your 3D model, transforming it into native data for work packaging. This integration capability facilitates better data analysis despite missing or imperfect data. This ability to handle missing, imperfect, or inconsistent data sets O3 apart from other AWP solutions. From the outset, O3 was designed to anticipate these real-world scenarios, ensuring that your project can continue to progress smoothly.

O3’s Integration Capabilities

O3 Solutions integrates missing data from various sources and fixes imperfect data using predefined rules. For instance, if equipment dimensions and weights are missing, O3 can integrate this information from different sources like the Equipment List or Vendor Data, making it part of the equipment for packaging purposes. Additionally, O3 considers other sources of data to ensure comprehensive data integration, addressing local variability and enhancing the accuracy of the data. This ensures that all necessary data is available for creating detailed and accurate work packages.

O3 Makes Working with Imperfect Data Easy

O3 also adapts to revised models with ease. When new model data arrives, O3 Solutions automatically processes it using the existing conditioning rules, eliminating the need for manual intervention. This feature saves time and effort, allowing your team to focus on more critical tasks.